Executive Summary

Not all chlorine dioxide (ClO₂) products are created equal. While competing extended-release systems may look similar on the surface, the raw material ratios and active ingredient content tell the real story.

This analysis shows three key truths:

- ClO₂ isn’t just ClO₂ — formulation matters. The type and ratio of chemicals determine the true potential of the product.

- Active ingredient sets the limit. ProKure D contains more sodium chlorite (the source of ClO₂) than competitor products, which means more potential gas output.

- Consistency is key. ProKure D delivers a steady concentration of ClO₂ across all sizes, while competitor products lose efficiency at scale.

The result: ProKure D consistently provides more gas, more predictably, and more efficiently than the competition.

1. Introduction: Reading between the label lines

When two products both say they release chlorine dioxide gas, it’s easy to assume they perform the same. But the truth is: ClO₂ isn’t just ClO₂.

The way a product is formulated — the chemicals used, the ratios between them, and the quality of ingredients — directly affects how much usable ClO₂ is produced. The limiting factor is always the active ingredient. With less of it, you simply can’t generate as much gas.

On top of that, it’s not enough to just generate ClO₂ — facilities need a consistent concentration to keep pathogens, mold, and odors under control. ProKure D not only has more active ingredient but also scales predictably, meaning whether you’re treating 1,000 ft³ or 8,000 ft³, you’ll always get a steady, reliable dose of ClO₂.

2. Product Overview

ProKure D

ProKure D is a dry, solid ClO₂-generating system using activated sodium chlorite. Designed for controlled gas release over periods up to 30 days, ProKure D is used in a variety of industries for its consistent output, scalability, and safety profile. It is designed to scale predictably with volume of space.

Competitor

The competitor offers an extended-release ClO₂ product line with similar intended applications. However, its product formulation and sodium chlorite content differ significantly, as does its theoretical ClO₂ output, especially across larger formats.

3. Methodology

This analysis is based on:

Manufacturer data for product size, active ingredient content (sodium chlorite), and intended coverage volume.

The theoretical stoichiometric conversion from sodium chlorite to ClO₂ (assuming full activation under ideal conditions).

Consistent 30-day rate of release of ClO2 across products.

4. Data Table: Active Ingredient and Product Efficiency

| Product | Product, g | Sodium Chlorite, g | Coverage, ft3 | Sodium Chlorite %wt. |

| Competitor | 72.5 | 16.6 | 10000 | 22.9 |

| Competitor | 56 | 11 | 4000 | 19.6 |

| Competitor | 43 | 9 | 2500 | 20.9 |

| Competitor | 37 | 7 | 1000 | 18.9 |

| ProKure D | 95 | 28.5 | 8000 | 30 |

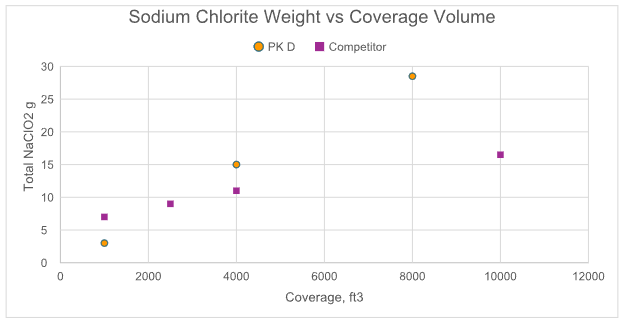

5. Active ingredient (sodium chlorite) available vs. Coverage Volume

This graph plots the weight of the active ingredient against the coverage area for both products.

Key Insights:

Both products show a linear dependance on coverage with the weight of active ingredients, but ProKure products contain up to 73% more active ingredients with increases in product size corresponding directly with increases in active ingredients.

The competitor products display fewer overall active ingredients for each of the coverage volumes, with bigger product sizes showing the largest difference.

This suggests that the competition has less overall coverage as well as significant efficiency loss at scale in larger treatment spaces.

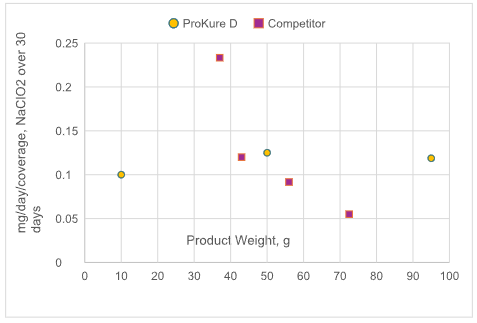

6. ClO₂ Release Efficiency vs. Product Weight

The second graph compares the active ingredient content equivalent to ClO₂ output, normalized for cubic feet of coverage and a 30-day release period, plotted against total product weight.

Key Insights:

ProKure D maintains a steady release efficiency across all sizes which is ideal for facilities needing uniform gas output regardless of treatment volume.

The competitor products lose efficiency as size increases, indicating diminishing returns in larger deployments.

In practical terms, ProKure’s efficiency allows for better coverage planning, cost control, and safety margin adherence.

7. Industry Application: Why It Matters

When you buy ProKure, you get what you pay for — and you know exactly what you’re getting. ProKure D consistently delivers the right amount of ClO₂ gas, at the right concentration, across all product sizes. That means your facility is always protected.

With the competitor’s products, you get less gas and less consistency. And when their product underperforms, your facility is left unprotected. Beyond safety and reliability, it’s simply a bad deal: paying the same price but getting only a fraction of the gas output.

For industries that can’t afford downtime or microbial risk, that difference matters.

8. Conclusion: The Case for ProKure D

| Criteria | ProKure D | Competitor |

| Yield per gram of product | ✅ Consistent | ⚠️Variable |

| Scalability with room size | ✅ Predictable | ❌ Inconsistent |

| Odor/mold/pathogen | ✅ Effective | ⚠️ Incomplete |

| Release efficiency | ✅ Optimized | ⚠️ Drops at scale |

This analysis clearly demonstrates that ProKure D products offer superior scalability, efficiency, and theoretical ClO₂ yield compared to the competitor’s extended-release systems.

For applications that require measurable, dependable, and safe long-term ClO₂ gas generation, ProKure D clearly outperforms.