Preventative Use of Chlorine Dioxide Liquid in Indoor Cultivation Media: ClO₂ (20ppm Pulse) for Coco | Rockwool | Peat | Hydro-Organic Systems

Indoor cultivation requires growers to create a balanced environment. Cannabis thrives when beneficial microbes are supported and pathogens are simultaneously eliminated. In other words, keep the good, kill the bad. Solutions that harmonize agriculture in controlled environments are simple to employ with the right IPM protocols in place. We recommend a 20ppm pulse of ClO₂ to your growing medium.

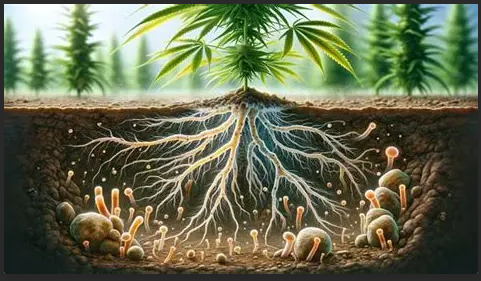

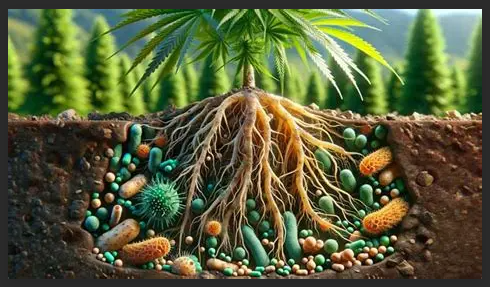

Maintaining a pathogen-free root zone without sacrificing the beneficial microbial consortium that drives yield and terpene quality remains the central challenge in controlled-environment commercial cannabis facilities. Conventional oxidizers (hydrogen peroxide, hypochlorous acid, peracetic acid, and ozone) are non-selective, meaning they collapse both good and bad populations, forcing repeated re-inoculation and creating boom-and-bust microbial cycles.

Chlorine Dioxide Brings Balance

Chlorine dioxide (ClO₂) is a special kind of disinfectant because it’s very selective in what it attacks. Most disinfectants kill everything indiscriminately, but ClO₂ targets certain weak points in harmful organisms—especially killing fungi and water molds like Pythium and Fusarium that cause plant diseases.

The reason? These pathogens rely on chemical structures called thiolates and iron–sulfur clusters for their energy systems. ClO₂ reacts with those structures extremely quickly, thousands of times faster than it reacts with similar structures in beneficial microbes (like Bacillus, Trichoderma, and Pseudomonas). This is how it knocks out the bad guys without harming the good ones.

ClO₂ boasts a standard reduction potential of +0.95 V (effectively ≈0.55–0.60 V at typical nutrient-solution pH 5.6–6.1). The numbers (+0.95 V, etc.) describe the chemical strength and how it behaves at the pH of a normal plant nutrient solution. The key takeaway here is that ClO₂ works because of real chemistry, not marketing hype—it’s selective by nature.

How to Harness the Power of Chlorine Dioxide

Instead of wiping everything out like sterilization, the goal is to rebalance the system. A single dose of chlorine dioxide at 20ppm knocks down harmful cannabis plant pathogens significantly. The good microbes barely take a hit—and they bounce back quickly, often turning up stronger because they fill the space left by the pathogens. The microbiome doesn’t just survive; it improves over time. Each treatment cycle makes things better, with no signs of resistance forming and almost no effect on water pH or equipment lifespan.

Implementation Instructions: Current Tier-1 Protocol (2025–2026 commercial standard)

Every 7 days during vegetative growth and the first 4–5 weeks of flower, then every 10–14 days thereafter, prepare a fresh 20ppm ClO₂ feed:

- Add the appropriate volume of activated ClO2 to the clean feed tank to achieve exactly 20ppm final concentration.

- Irrigate to 15–25 % runoff for complete media saturation, allow a 4-to-6-hour dwell (overnight is common and perfectly acceptable).

- Resume normal feeding at the next irrigation (nutrient and beneficial inoculant). No flush is required.

This weekly 20ppm pulse of ClO₂ is part of most commercial cannabis cultivation IPM programs to maintain root-zone pathogens below detectable levels while the beneficial consortia continue to dominate and increase in density through harvest. As a bonus, the 20ppm pulse helps prevent root rot.

Important tip: Chlorine dioxide (ClO₂) is great at breaking up biofilms inside irrigation lines. If your system already has a lot of buildup, the first couple of treatments might loosen debris and cause temporary clogs in emitters. Doing a quick preclean or flushing the lines before starting prevents this problem.

Once the system is clean, this method works reliably. Indoor growing needs a balanced environment—where helpful microbes thrive and harmful bacteria are kept under control. This protocol makes it easy for growers to maintain healthy plants and a stable, productive system. Add this to your cannabis IPM program or grow room mold control SOP to help reduce mold before it becomes a problem.