Executive Summary

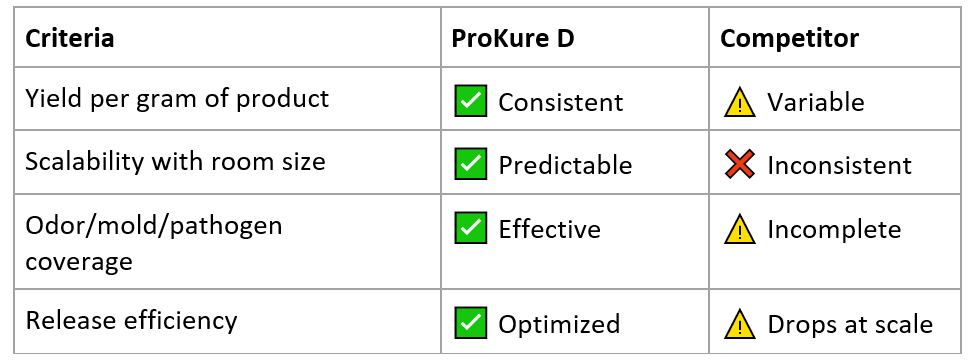

Not all extended-release chlorine dioxide (ClO₂) products perform the same — even when they claim to. While several brands market their systems as comparable in coverage and duration, this analysis shows significant differences in both total gas generation and consistency of release.

ProKure D products deliver more ClO₂ gas per cubic foot of coverage — and do so predictably and continuously over the full treatment period. In contrast, the competitor’s products produce less total gas, with uneven release patterns marked by short-lived spikes followed by steep declines. Their largest format, marketed for 10,000 cubic feet, fails to maintain effective ClO₂ concentrations across the stated volume.

By contrast, ProKure D maintains consistent gas generation and concentration across all product sizes and space volumes, ensuring reliable coverage, safety and odor control. For operations that depend on measurable, continuous protection — including cannabis cultivation, post-harvest storage, and restoration — consistency isn’t just a feature; it’s the difference between effective and ineffective treatment

Introduction: Why All ClO₂ Gas Products Are Not Created Equal

Chlorine dioxide (ClO₂) is a trusted antimicrobial gas used across industries for its ability to neutralize bacteria, viruses, mold, and odor-causing compounds. Extended-release systems make it possible to maintain that protection over weeks — but product performance varies dramatically from brand to brand.

Many extended-release systems claim similar coverage, duration, and efficacy. However, these claims overlook key technical factors that determine whether a product actually delivers effective ClO₂ concentrations throughout a space: the concentration of active ingredients, the rate and stability of gas release, and whether the product scales reliably with room volume.

This analysis compares ProKure D to a leading competitor and demonstrates a critical fact: products that appear equivalent on paper are not equivalent in performance. The competitor’s systems deliver less gas per cubic foot and release it unevenly, while ProKure D consistently generates the expected ClO₂ output and maintains stable concentrations over time.

For facilities relying on continuous microbial control — whether protecting harvests, remediating mold, or maintaining clean grow spaces — those differences determine real-world results.

Product Overview

ProKure D

ProKure D is a dry, solid chlorine dioxide (ClO₂)–generating system engineered for consistent, extended gas release over a period of up to 30 days. Unlike competitor products, ProKure D is formulated with a higher concentration of sodium chlorite, ensuring a predictable and scalable ClO₂ output. This consistency is critical for maintaining effective Cl02 protection in environments where coverage reliability and safety are non-negotiable.

Competitor

Competitor products, while designed for similar applications, show significant variability in the active ingredient content (sodium chlorite) and demonstrate inconsistent scaling. As product size increases, their efficiency drops, leading to uneven gas distribution and diminished performance in larger spaces.

In short, ProKure D’s superior formulation and performance characteristics make it the more dependable choice for long-term, scalable ClO₂ coverage.

Methodology

This analysis is based on manufacturer data for product size, active ingredient content (sodium chlorite), intended coverage volume, and consistent 30-day rate of release of ClO₂ across products.

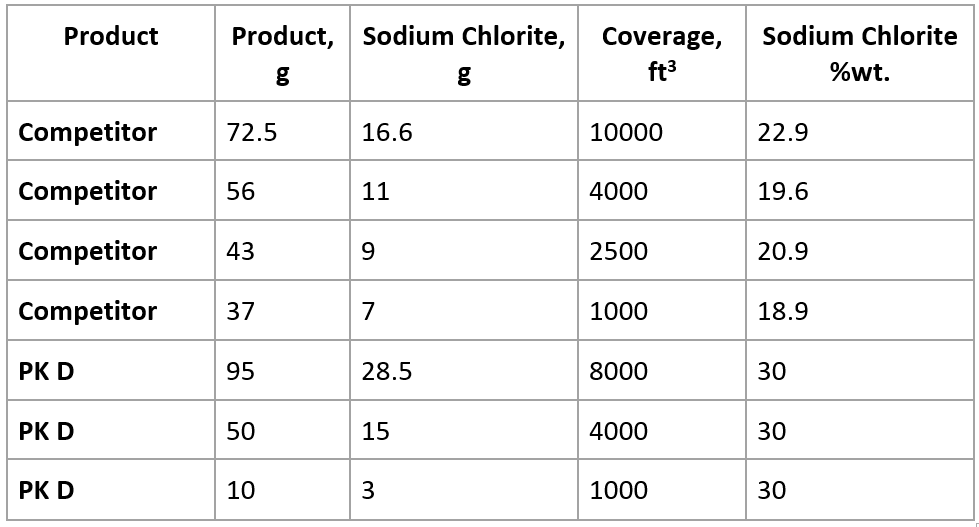

ClO2 Active Ingredient & Product Efficiency Data Table

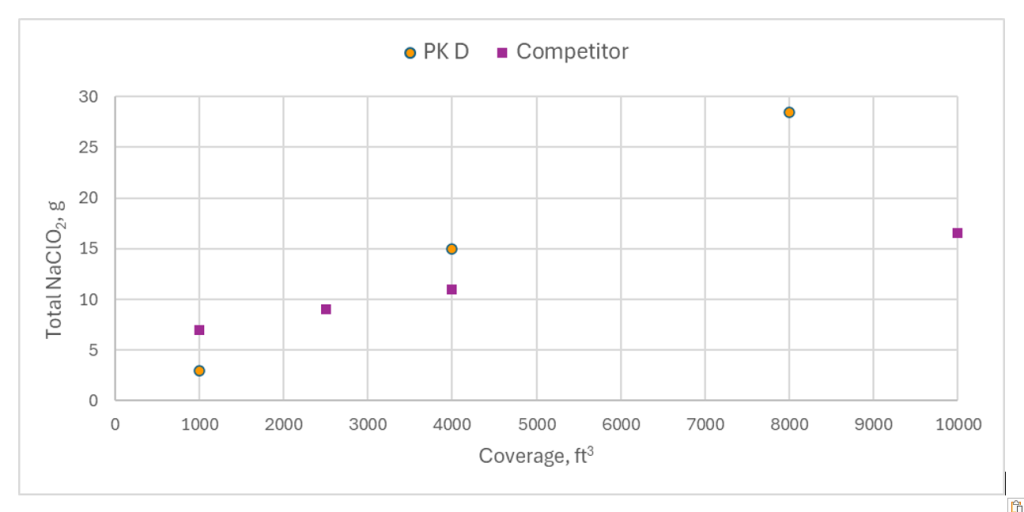

Active Ingredient Available vs. Coverage Volume

Graph Notes: This graph plots the weight of sodium chlorite against the coverage area for both ProKure and Competitor products.

In summary both ProKure and the competitor increase the ingredient amount as the coverage area grows, but ProKure adds a lot more—up to 73% more. That means ProKure is more powerful and efficient, especially in bigger spaces. The competitor uses less of the active ingredient, which can lead to weaker performance and less reliable coverage when treating large areas.

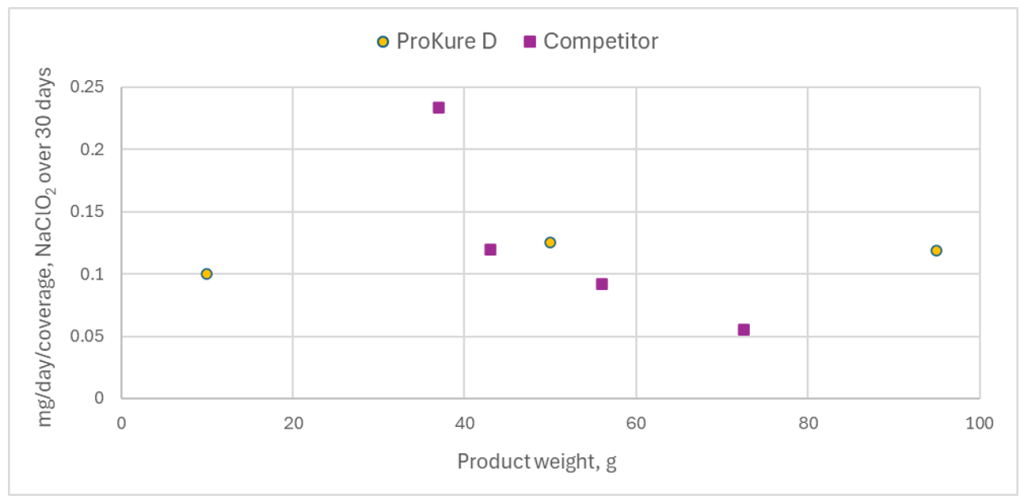

ClO₂ Release Efficiency vs. Product Weight

Graph Notes: This graph plots the weight of sodium chlorite against the coverage area for both ProKure and Competitor products.

In summary both ProKure and the competitor increase the ingredient amount as the coverage area grows, but ProKure adds a lot more—up to 73% more. That means ProKure is more powerful and efficient, especially in bigger spaces. The competitor uses less of the active ingredient, which can lead to weaker performance and less reliable coverage when treating large areas.

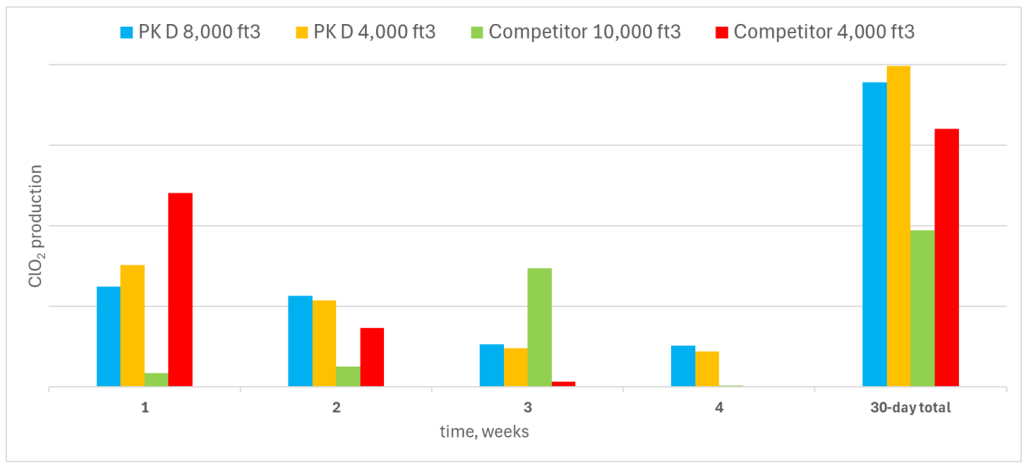

Weekly Production of ClO2 Gas

Graph Notes: The final graph illustrates the relative ClO₂ gas release over a 30-day period from four different products under controlled environmental conditions (74–78°F, 55–65% RH), normalized to their stated coverage volumes. PK products (4,000 ft3 and 8,000 ft3) demonstrated more consistent and sustained ClO₂ production across the four-week period compared to competitor products. PK D 4,000 ft3 yielded the highest total ClO₂ output over 30 days, followed closely by PK D 8,000 ft3. In contrast, the 4,000 ft3 competitor product released a large amount of ClO₂ in the first week but declined sharply thereafter. The 10,000 ft3 competitor showed a delayed release pattern, with a spike in week 3, but produced the lowest total ClO₂ over the test period, as predicted by the previously stated lack of active ingredients. These results suggest that PK products deliver more reliable and efficient ClO₂ release relative to labeled coverage areas.

In summary this graph shows that ProKure products release their gas steadily over 30 days, while competitor products are unpredictable—sometimes releasing too much at once or not enough. Because ProKure is consistent, it’s easier to plan how much you need, stay within safety limits, and avoid wasting money or product.

Why It Matters

Why These Differences Matter

- Consistent Output = Reliable Coverage

ProKure D’s steady ClO₂ release ensures that every cubic foot of treated space receives uniform ClO2 protection. This is essential in industries like cannabis cultivation & even restoration, where uneven coverage can lead to problems down the line. - Scalability = Cost Efficiency

Facilities can confidently scale ProKure D products to match room size without sacrificing performance. This predictability reduces the need for over-application, minimizes waste, and simplifies planning. - Higher Active Ingredient = Greater Efficacy

With up to 73% more active ingredient per gram of product compared to competitors, ProKure D delivers more ClO₂ gas over time—translating to better coverage. - Stable Release Profile = Safety & Compliance

ProKure D maintains a steady release rate, avoiding the erratic spikes and drop-offs seen in competitor products. This helps facilities stay within recommended exposure thresholds and ensures safer re-entry conditions.

Conclusion: The Case for ProKure D

This analysis demonstrates that ProKure D products offer superior scalability, efficiency, and theoretical ClO₂ yield compared to Competitor extended-release systems.

For applications that require measurable, dependable, and safe long-term ClO₂ gas generation, ProKure D clearly outperforms.